AIR ATOMIZING AND MISTING NOZZLES

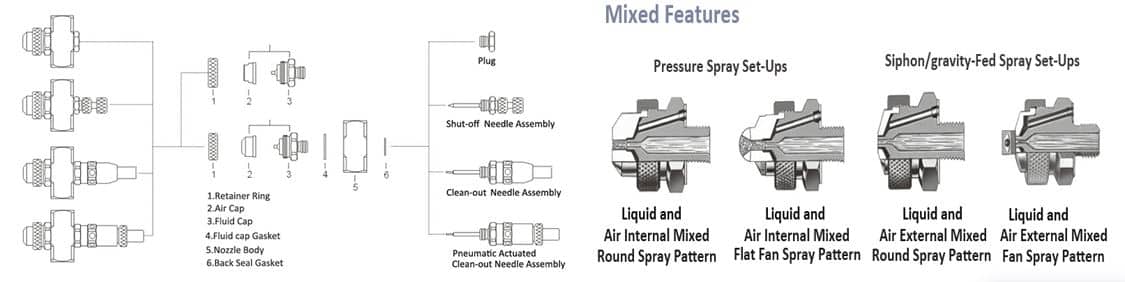

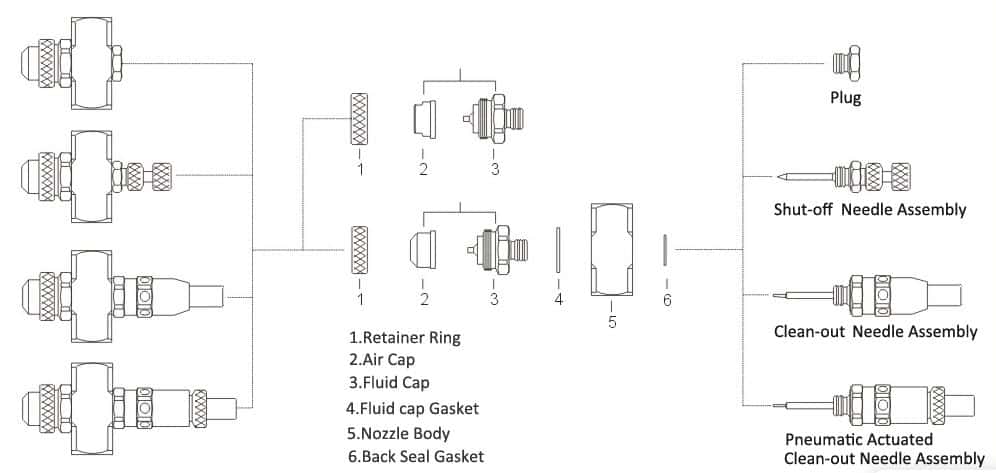

Air and Liquid Fed Atomizing Nozzle

General technical specifications of air and liquid fed atomizing nozzles:

Spray Angle : 15˚ – 70˚

Spray Pattern : Full-cone / flat fan

Thread Size : 1/8″ – 1/4″

Material : Stainless steel

Thread type : Female , NPT / BSPT

Internal or external mix, pressure / siphon type

Adjustable flow (by needle) / fix (without needle)

Air and liquid fed working principle

Application area : Dust control, coating, lubrication, cooling, humidification, etc.

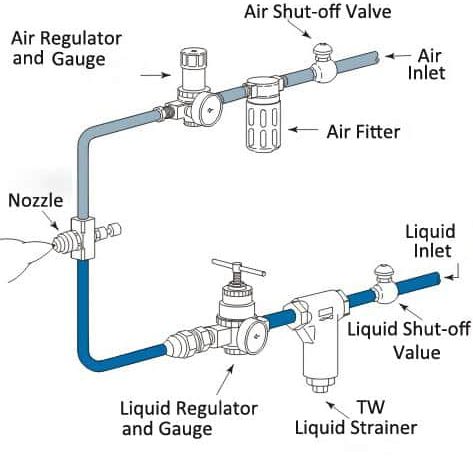

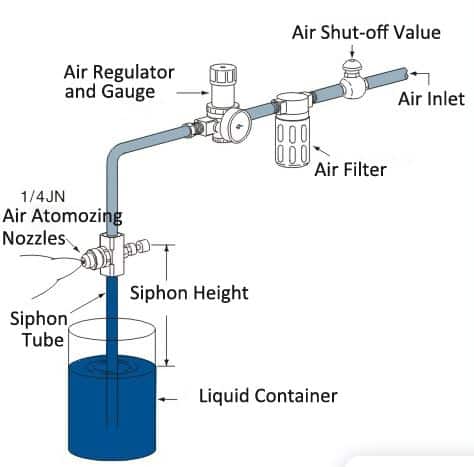

INSTALLATION METHOD

PRESSURE SET UP

SIPHON OR GRAVITY-FED LIQUID SET-UPS

Ultrasonic Dry Fog Nozzle

Common technical characteristics of ultrasonic dry fog nozzles:

Spray Angle : 15˚ – 80˚

Spray Pattern : Conical

Thread Size : 1/8″ , 1/4″

Material : Stainless Steel

Thread Type : Female , BSPT / NPT

Drop Size : Approx. ∼ 10-50 µm

Air and liquid fed working principle

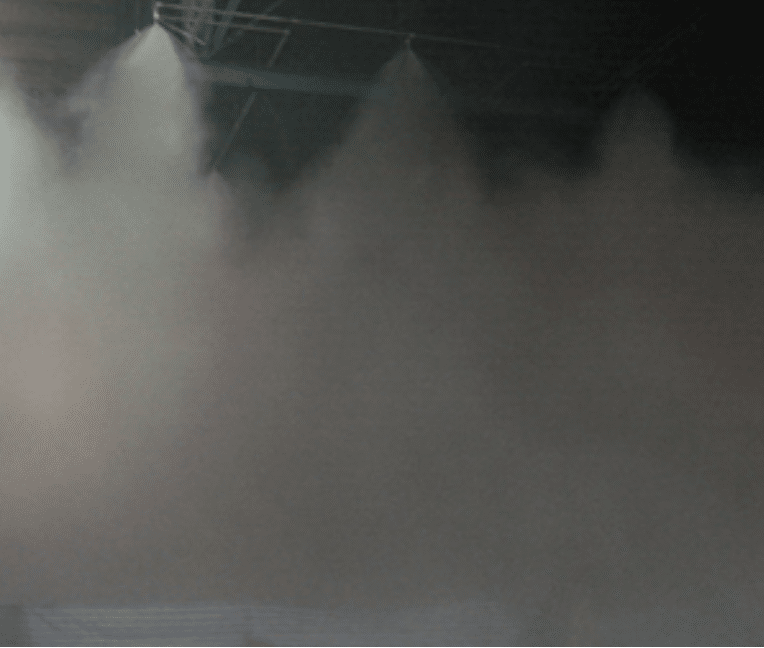

Application area : Misting, humidification, dust suppression, pulverize some different contents of liquids, making mist curtain

Fine Mist Nozzle

Common technical characteristics of fine mist nozzles:

Spray Angle : 45˚ – 165˚

Spray Pattern : Full-cone / hollow cone

Thread Size : 1/4″

Material : Stainless Steel

Thread Type : Female / male BSPT / NPT

Hydraulic pressure fed.

Application area : Fire prevention, cooling, dust suppression, metal treatment, gas cooling, misting, humidification, eliminate static electricity of environment

Fine Mist Nozzle Application -1

Fine Mist Nozzle Apllication -2

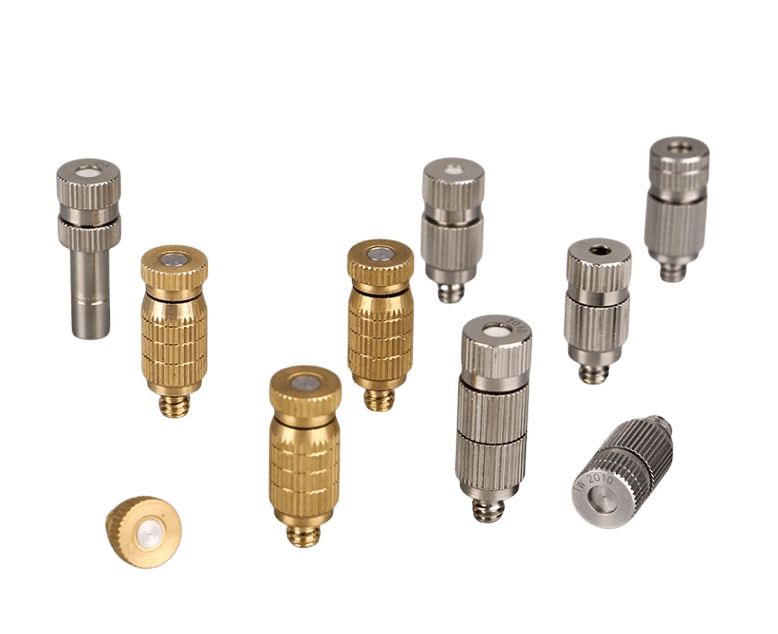

Mist Nozzles

Common technical characteristics of mist nozzles:

Spray Angle : 50˚

Spray Pattern : Conical

Thread Size : 3/16″, 10/24

Material : Stainless Steel, brass (nozzle core is stanless steel)

Thread Type : Male BSPT / NPT

Drop Size : Approx. 5-50 µm

High / low pressure

Hydraulic pressure fed.

Application area : Cooling, dust suppression, misting, humidification, odor suppression, etc.

Oil Burner Nozzle - Filtered

Common technical characteristics of oil burner nozzles:

Spray Angle : 50˚- 90˚

Spray Pattern : Conical

Thread Size : 1/4″

Material : Stainless Steel

Thread Type : Male BSPT / NPT

Drop Size : Approx. 50 – 230 µm

Hydraulic pressure fed.

Filtered.

Application area : Lubrication, dust suppression, cooling, water conditioning, misting, humidification, etc.

Fine Mist Pin Nozzle - Filtered

Common technical characteristics of fine mist pin nozzles:

Spray Angle : 90˚

Spray Pattern : Conical

Thread Size : 1/8″

Material : Stainless Steel

Thread Type : Male BSPT / NPT

Hydraulic pressure fed.

Filtered.

In some conditions, it can take on the role of air atomizing nozzles.

Application area : Cooling, humidification, temperature control, disinfection, chemical liquids spraying, dedusting, etc.

Fog Cannon Nozzle

Common technical characteristics of fog cannon nozzles:

Spray Angle : 15˚ – 65˚

Spray Pattern : Conical

Thread Size : 1/4″

Material : Stainless Steel

Thread Type : Female / male, BSPT / NPT

Hydraulic pressure fed.

Rotating head for flow regulate.

If an air fan is reinforced, spray distance can reach between 30 to 100 meters

Application area : Dust suppression, disinfection, fire prevention, dust removing, humidification, cooling, etc.

Automatic Atomizing Nozzle

Common technical characteristics of automatic atomizing nozzles:

Spray Angle : 45˚ / 80˚ / 110˚

Spray Pattern : Flat or irregular ellips

Thread Size : 1/8″, 1/4″

Material : Stainless Steel

Thread Type : Female, BSPT / NPT

Drop Size : 20 µm – 100 µm

Body : Nozzle tip, head, connector as set.

Air and liquid fed working principle.

The gas driven internal part controls the switch, it can cycle 180 times per minute.

Application area : Lubrication, metal treatment spraying, disinfection, coating, humidification, cooling, etc.

Applications:

* Water cooling : Cooling of metals, conveyor belt, machines

* Dust control : Building construction, control the coal ash, sand, crushed stones, slag ash, garbage sweeper

* Degreasing : Industrial equipments, bottle and food production process cleaning

*Chemical processing : Sterilization, pharmaceutical production process

* Gas cooling / scrubbing : Glazed tiles and coloured tiles, industrial gas cooling

* Thermal power plant, desulphurization, chemical plant, metal treating, environmental engineering

* Misting : In order to occur a good quality atmospheric condition.