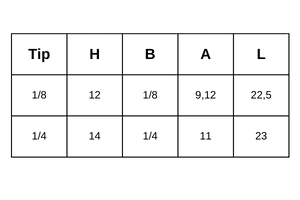

Flat Fan Nozzles

Stainless Steel Flat Fan Nozzles

Common technical specifications of flat fan nozzles:

Spray Angle : 15˚ – 110˚

Thread Size : 1/8″, 1/4″, 1/2″

Thread Type : Male, BSPT / NPT

Material : Stainless steel, brass, PP, PVC

Pressure Range : Between 1 – max. 200 bar (for stainless steel nozzles)

Application area : Water curtain, coating, metal treatment, rinsing, cleaning, etching, gas cooling, washing, degreasing, etc.

Flat Fan Tips

Common technical specifications of flat fan nozzles:

Spray Angle : 15˚ – 110˚

Material : Stainless steel, brass, tungsten ( tip core)

Pressure Range : Between 1 – 10 bar (for stainless steel nozzles), between 50 – 200 bar (for tungsten)

Drop Size : Small to medium, in a wide flow range, smooth distribution

Application area : Water curtain, coating, metal treatment, rinsing, cleaning, etching, gas cooling, washing, degreasing, spraying hard particules

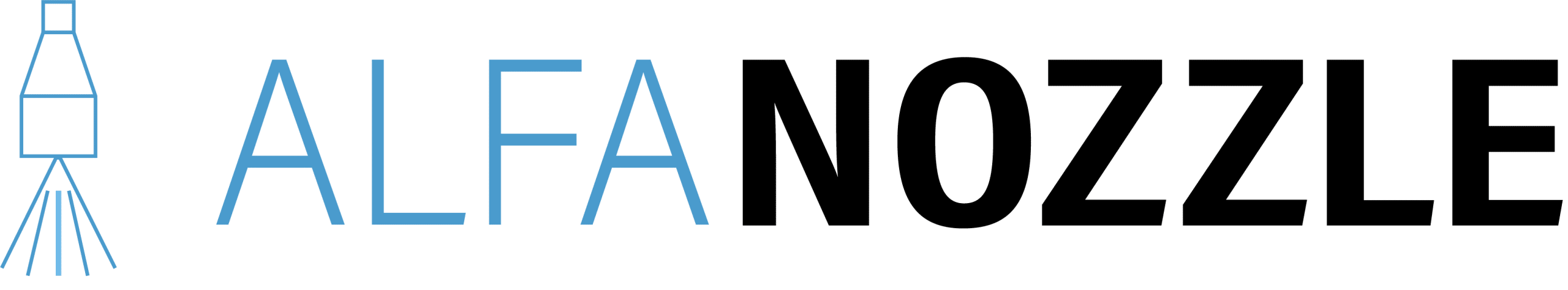

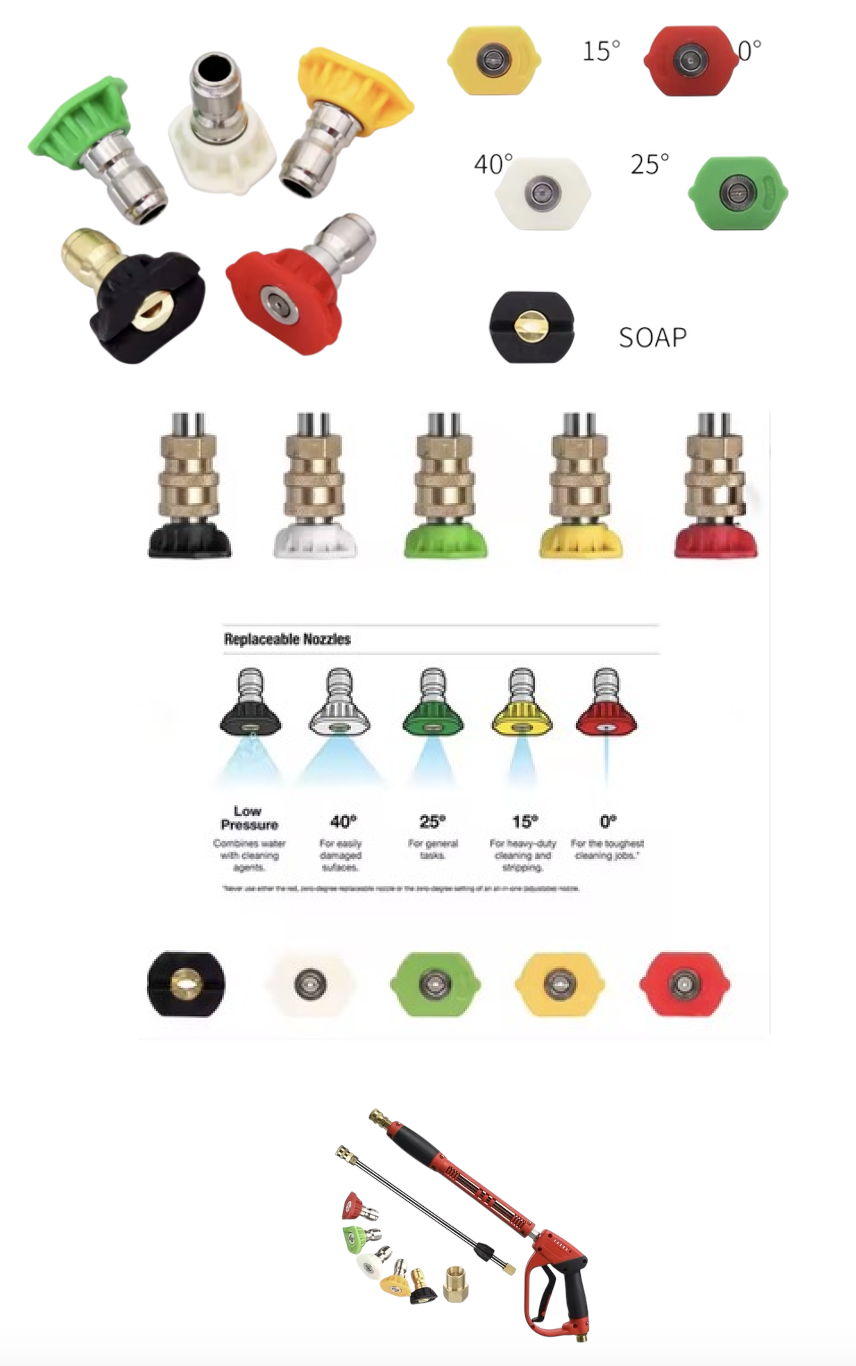

High Pressure Rinsing and Foam Nozzles

Common technical specifications of high pressure rinsing and foam nozzles:

Spray Angles : Red 0˚, Yellow 15˚, Green 25˚, White 40˚, Black 65˚

Fitting : 1/4″ quick connect plug

Material : 304 stainless steel for rinsing and foaming or brass only for foaming

Pressure : Max. 275 bar

Usage area :

Red 0˚ : To clean high or hard to reach areas, such as crevices in sidewalks and driveway.

Yellow 15˚ : To clean brick, concrete and other hard surfaces with stubborn stains.

Green 25˚ : To clean wood, fences, painted surfaces, siding and lawn mowers.

White 40˚ : To clean screens, windows, etc.

Black 65˚ : Foaming, to spray detergents.

Max. Temperature : 70˚C

Stainless Steel Aisi 316 W Type Flat Fan Nozzle

V Narrow Angle Deflector Flat Fan Nozzle

Stainless Steel 3 Combination - Replaceable Tip Nozzle

Flat Fan Cleaning Nozzle

PP / SS Single or Double Clamped Clip-on or Adjustable Ball Nozzles

Common and diversified general technical specifications of the clip-on nozzles and adjustable ball plastic nozzles:

Spray Angle : 15˚ – 25˚ – 40˚ – 50˚ – 65˚ – 80˚

Pressure Range : 0.3 – 4 bar

Adjustable Ball Thread Size : 1/8″, 1/4″, 3/8″, 1/2″

Installation : Clip-on (clamped) or adjustable ball (threaded)

Pipe Orifice : 14 mm, 16 mm, 18 mm

Clip-on Types : Single or double clamped

Clamp Sizes : 3/4″, 1″, 1-1/4″, 1-1/2″

Clamp Outside Dimension : 25-27 mm, 32-35 mm, 38-43 mm, 44-51 mm

Clip-on / Adjustable Ball Material : PP, PVC, PTFE, SS

Easy and fast installation.

Adjustable ball orientation allows quick change of nozzle direction.

It provides easy inspection and cleaning thanks to its removable cap and valve.

Usage area : Metal surface treatment, degreasing, phosphating, spray cooling, fire prevention, dust control, washing, etc.

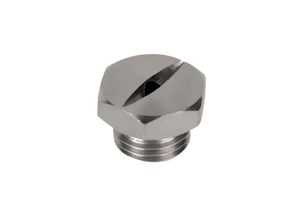

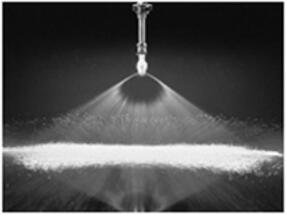

FLAT FAN SPRAY NOZZLE FLOW TYPE (SURFACE IMPACT) PICTURE

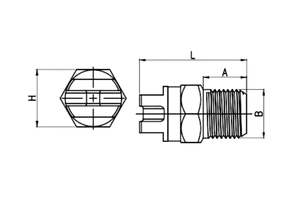

A SAMPLE DRAWING AND A SAMPLE DIMENSIONS OF A STANDARD FLAT FAN NOZZLE

Common technical specifications of w type flat fan nozzles:

Spray Angle : 73˚ – 138˚

Thread Size : 1/8″ – 1″

Orifice Size : 0,43 mm – 18,0 mm

Material : Stainless steel 304 / 316, PP

Thread Type : Male, BSPT / NPT

Uniform distribution over a wide range of flow rates and pressures.

Unobstructed flow passages minimize clogging.

W TYPE WIDE ANGLE SPRAY NOZZLE FLOW TYPE (SURFACE IMPACT) PICTURE

V Type Deflector - Narrow Angle Spray Nozzle

Common technical specifications of w type flat fan nozzles:

Spray Angle : 15˚ – 50˚

Thread Size : 1/8″ – 3/4″

Orifice Size : 1,3 mm – 8,4 mm

Material : Stainless steel 304 / 316, PP, PVC, PTFE, brass

Thread Type : Male, BSPT / NPT

Uniform distribution over a wide range of flow rates and pressures.

Integrated flow surface design, high-effective flat fan spray pattern, clear edge, uniform distribution.

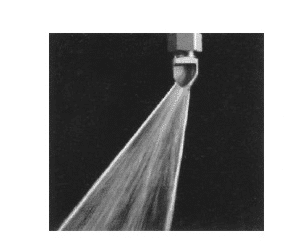

V TYPE DEFLECTOR – NARROW ANGLE SPRAY NOZZLE FLOW TYPE (SURFACE IMPACT) PICTURE

Scope Of Application

* Water cooling :

Cooling of primary materials and other materials, conveyor belt, metal parts and machinery

* Dust control :Dust control of building construction, cool ash, sand, crushed stone, slag ash and garbage sweeper

* Degreasing : Cleaning of industrial workpieces, cleaning and degreasing of bottle and food manufacturing processes.

* Chemical process :Sterilization, drug production process

* Gas cooling and gas cleaning : Tiles/ glazed tiles or bricks and colored tiles / ceramics, industrial gas cooling and gas cleaning of various facilities

Fan Nozzle Codes We Produce:

6550 Nozzles, 6540 Nozzles, 6530 Nozzles, 6520 Nozzles, 6515 Nozzles, 6510 Nozzles, 6508 Nozzles, 6506 Nozzles, 6505 Nozzles, 6504 Nozzles, 6503 Nozzles, 6502 Nozzles, 6501 Nozzles.