Full-Cone Spray Nozzles

Narrow Angle Full Cone Spray Nozzle

Standard Angle Full Cone Spray Nozzles

Standard Angle Full Cone Spray Nozzle - Allen Head

Wide Angle Full Cone Spray Nozzle - Allen Head

Wide Angle Full-Cone Spray Nozzle

Standard Angle Square Cone Nozzle - Allen Head

Common Technical Specifications of Full Cone Nozzles:

- Spray Pattern : Full Cone Spray

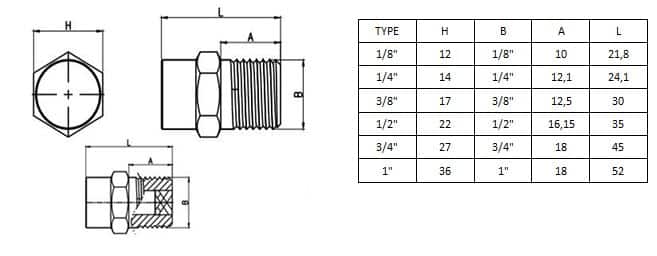

- Thread Sizes : 1/8″ – 1″

- Thread Type : Male / Female , NPT / BSPT

- Valved design

- Homogeneous spray distribution

- Material : PP / Stainless Steel aisi 303 / 304 / 316

Full Cone Pressure Washer Spray Nozzle For Surface Treatment

Common technical specifications of standard angle full cone nozzles:

- Spray Angle : 43˚ – 94˚

- Thread Size : 1/8″ – 1″

- Orifice Size : 0,79 mm – 11,9 mm

- Material : PP / Stainless Steel aisi 303 / 304 / 316

- Thread Type : Male / Female (only for special requests) , NPT / BSPT

- Spray Pattern : Full cone spray pattern from medium to wide angle

- Internal valve design provides superior flow control and homogeneous spraying.

- Unobstructed flow passages minimize clogging.

FULL-CONE SPRAY NOZZLE FLOW TYPE (SURFACE IMPACT) PICTURE

A SAMPLE DRAWING AND A SAMPLE DIMENSIONS OF A STANDARD FULL-CONE NOZZLE

NARROW ANGLE FULL CONE NOZZLE TYPE (SURFACE IMPACT) PICTURE

NARROW ANGLE FULL CONE SPRAY NOZZLES

Wide Angle Full Cone Spray Nozzle

Common technical specifications of wide angle full cone nozzles:

- Spray Angle : 102˚ – 124˚

- Thread Size : 1/8″ – 2″

- Orifice Size : 1,6 mm – 25 mm

- Material : PP / Stainless Steel aisi 303 / 304 / 316

- Thread Type : Male / Female ( only for special requests), NPT / BSPT

- Spray Pattern : Wide angle full cone spray pattern

- Internal valve design provides superior flow control and homogeneous spraying.

- Unobstructed flow passages minimize clogging.

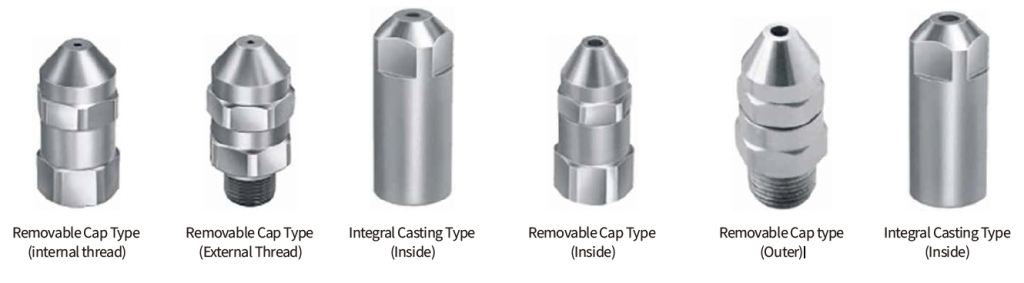

All full cone spray nozzles offer uniform distribution over a wide range of flow rates and pressures. Many model shave removable caps and valves for easy inspection and easy cleaning. The PP material option offers exceptional chemical and corrosion resistance, resists caking and build up. There is a wall mount option for installation outside the room in tank or pipe line. Right-angle mounting options allow mounting at a 90° angle for space-limited installations.