Tank Cleaning Nozzles

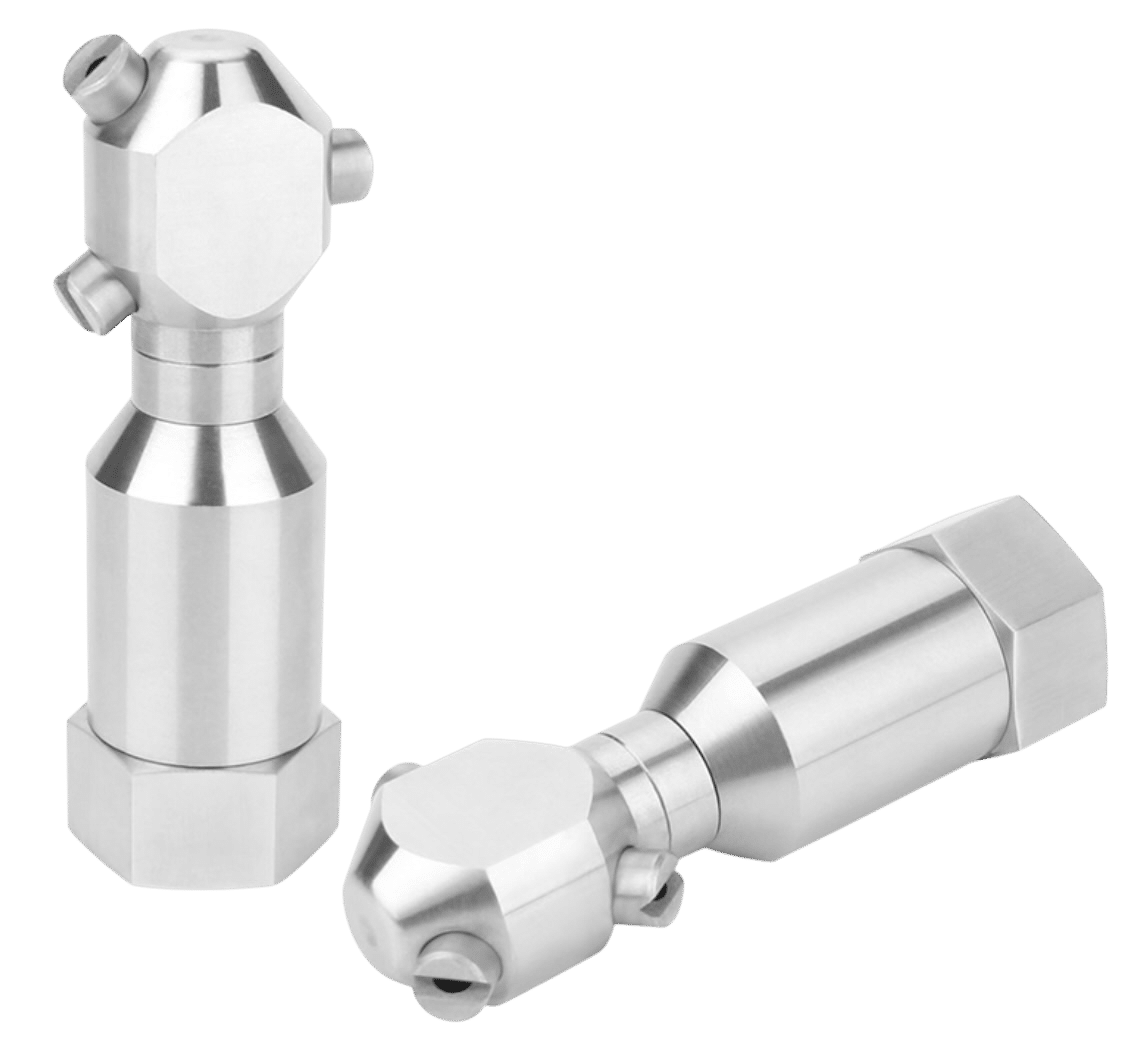

360˚ Rotary Spray Ball Cleaning Nozzle - CIP

General technical specifications of 360˚ rotary spray ball cleaning CIP nozzles:

- Thread Size : 3/8″ – 1 1/2″

- Material : 304 / 316 aisi stainless steel

- Pressure : 1- 5 bar

- Connection Type : Pinned / female thread – NPT / BSPT

- Max. Temperature : 100˚C

- It is used for internal cleaning of various tanks and tankers.

360˚ Fixed Tank Cleaning Nozzle - Clip-on

360˚ FIXED TANK WASHING NOZZLE FLOW TYPE (SURFACE IMPACT) EXAMPLE

360˚ Fixed Tank Cleaning Nozzle - Welded

General technical specifications of the 360˚ fixed tank cleaning nozzles:

- Thread Size : 3/4″ – 2″

- Material : 304 / 316 aisi stainless steel

- Pressure : 1- 5 bar

- Connection Type : Threaded – NPT / BSPT , welded , clip-on , pin bolted

- Max. Temperature : 100˚C

360˚ Rotating IBC Spray Tank Cleaning Nozzle

General technical specifications of the 360˚ rotating IBC spray tank cleaning nozzles:

- Thread Size : 3/8″ – 1 1/4″

- Material : 304 / 316 aisi stainless steel

- Pressure : 1,5 – 12 bar

- Connection Type : Female threaded NPT / BSPT

- Max. Temperature : 100˚C

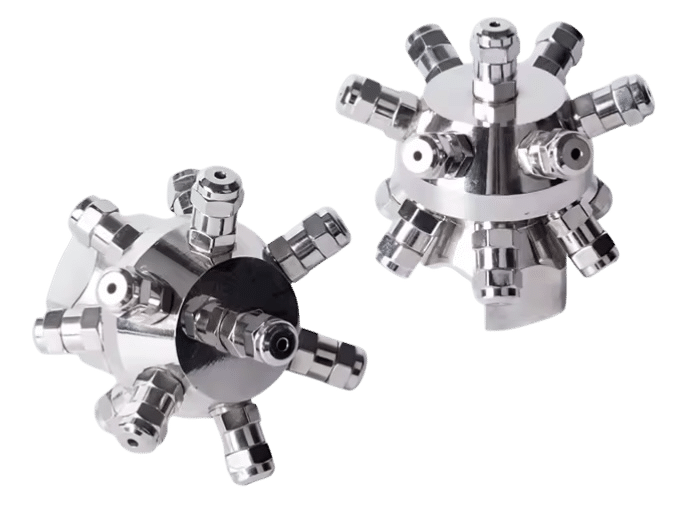

360˚ Fixed IBC Tank Cleaning Nozzle

General technical specifications of the 360˚ fixed IBC tank cleaning nozzles:

- Thread Size : 1/2″ , 3/4″ , 1″ , 1 1/2″

- Material : 304 / 316 aisi stainless steel

- Pressure : 1,5 – 4 bar

- Connection Type : Female threaded NPT / BSPT

- 13 pieces of full cone nozzle tips

- Max. Temperature : 100˚C

3- Flat Tips 360˚ Rotary Tank Cleaning Nozzle

General technical specifications of 3-tips 360˚ rotary tank cleaning nozzles:

- Thread Size : 1/2″ , 3/4″ , 1″

- Material : 304 / 316 aisi stainless steel

- Pressure : 1 – 4 bar

- Connection Type : Female threaded NPT / BSPT

- 3 pieces of flat fan nozzle tips

- Max. Temperature : 100˚C

TANK WASHING NOZZLES APPLICATION AREAS: Used to clean silt inside sewage tanks, railcars, tankers, water supply tanks, pharmaceutical tanks, food processing tanks, storage tanks, and small and medium-sized tanks in the pharmaceutical, beverage, and chemical industries, or for equipment chamfering operations on barrels, reaction vessels, and tank containers.